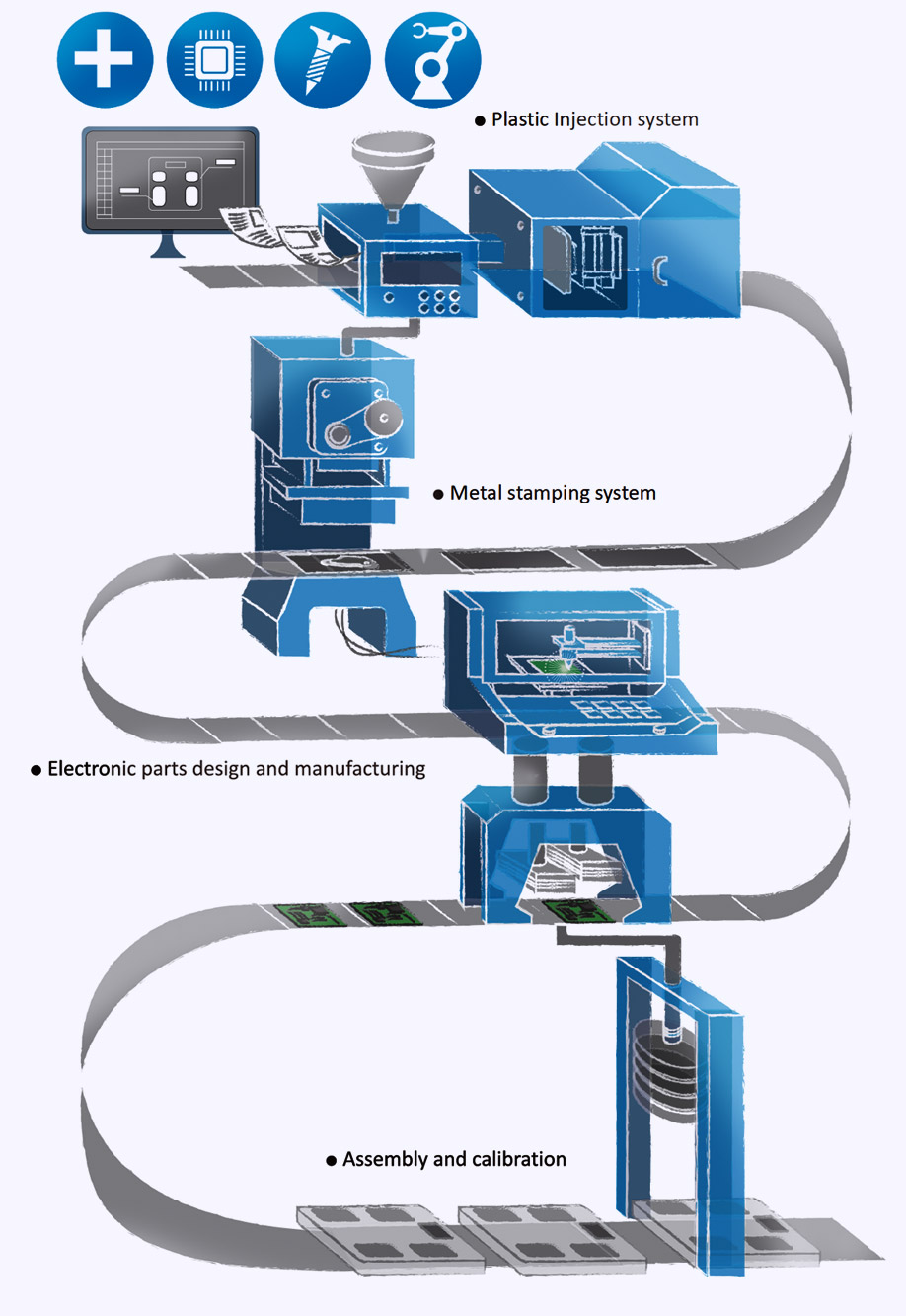

Manufacturing Capabilities

A FULL SERVICE APPROACH

A wide array of manufacturing and production services.

Charder’s competitive advantage is our ability to develop your product from concept to delivery. We can design and produce prototypes, run small quantities with soft-tooled processes, and migrate to hard tooling as quantities increase. Clients can choose the most suitable stage for entry and exit within our Full Service Approach.

Over 30 years of experience

Charder’s years of experience in producing measuring devices has given us the tools to provide professional and technical assistance to clients, creating ideal OEM/ODM partnership opportunities.

Supply Chain network optimization

We’ve optimized our supply chain network to provide complete upstream and downstream integration solutions, helping clients to minimize logistical costs and time.

Flexible product production process

Devoted to the manufacture of measurement and health management products, Charder offers a diverse variety of sensor designs and strain gauge applications. Using advanced production testing machines, automatic calibration and verification is used throughout the process to ensure product quality and accuracy.

Diverse product applications

Charder has experience in developing components for a number of industries. We work closely with customers from various industries to develop new smart applications for existing and nascent technology.

Project management system

Protecting our client’s intellectual property is an utmost priority. Charder has created a rigorous management system and protocol to protect each exclusive design, utilizing a product development process that enables us to meet client’s project goals.